solar-powered-weather-station

built a weather monitoring station that measures temperature, humidity, pressure, particulate matter, and CO₂. The data is processed in real time, and is all housed within a 3D-printed enclosure for accurate indoor or outdoor monitoring.

Build:

Output Data:

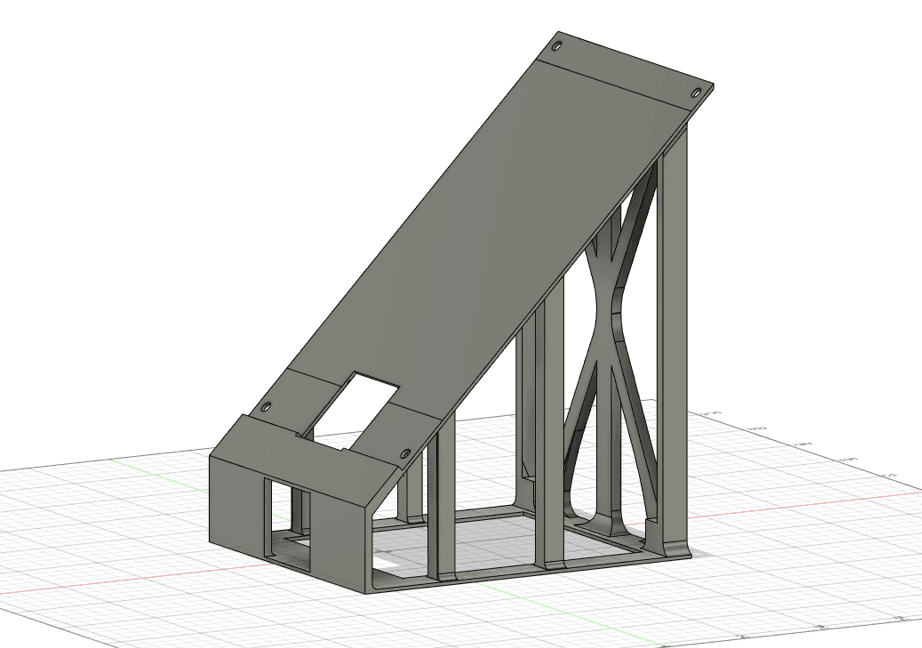

Mechanical / Enclosure Design:

Utilized a custom 3D-printed enclosure based on a modular, layered Stevenson screen for environmental shielding

Designed internal mounting structures for:

Sensor modules

ESP32 controller board

Battery pack and charge controller

Cable routing channels for clean and protected wiring

Included a top-mounted solar panel bracket for optional off-grid power operation

Printed the housing using weather-resistant white PLA/PETG to minimize heat absorption and ensure long-term durability

Optimized vent spacing to allow natural convection airflow while preventing water ingress and limiting direct solar heating of sensors

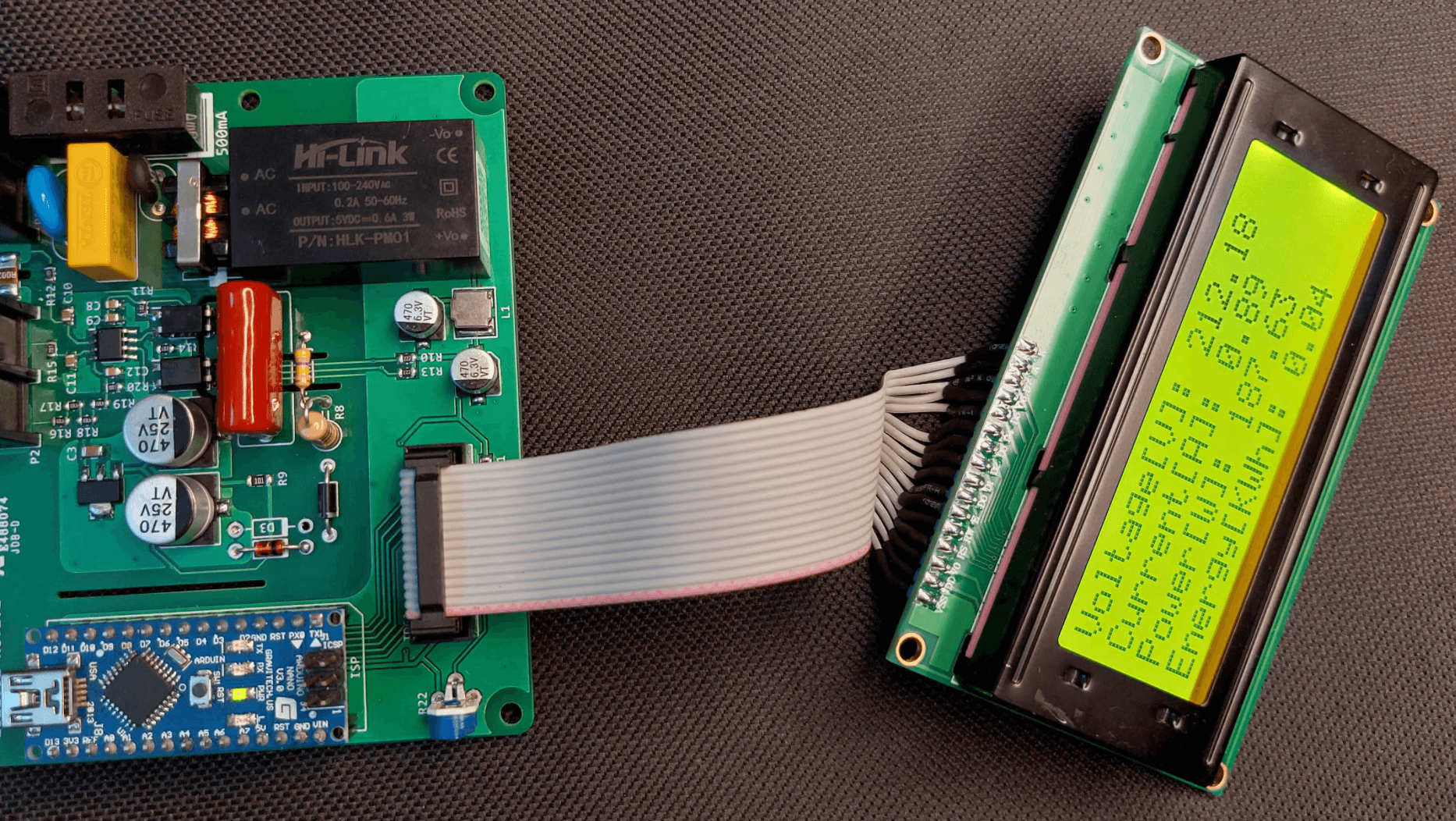

PCB Design/Schematic

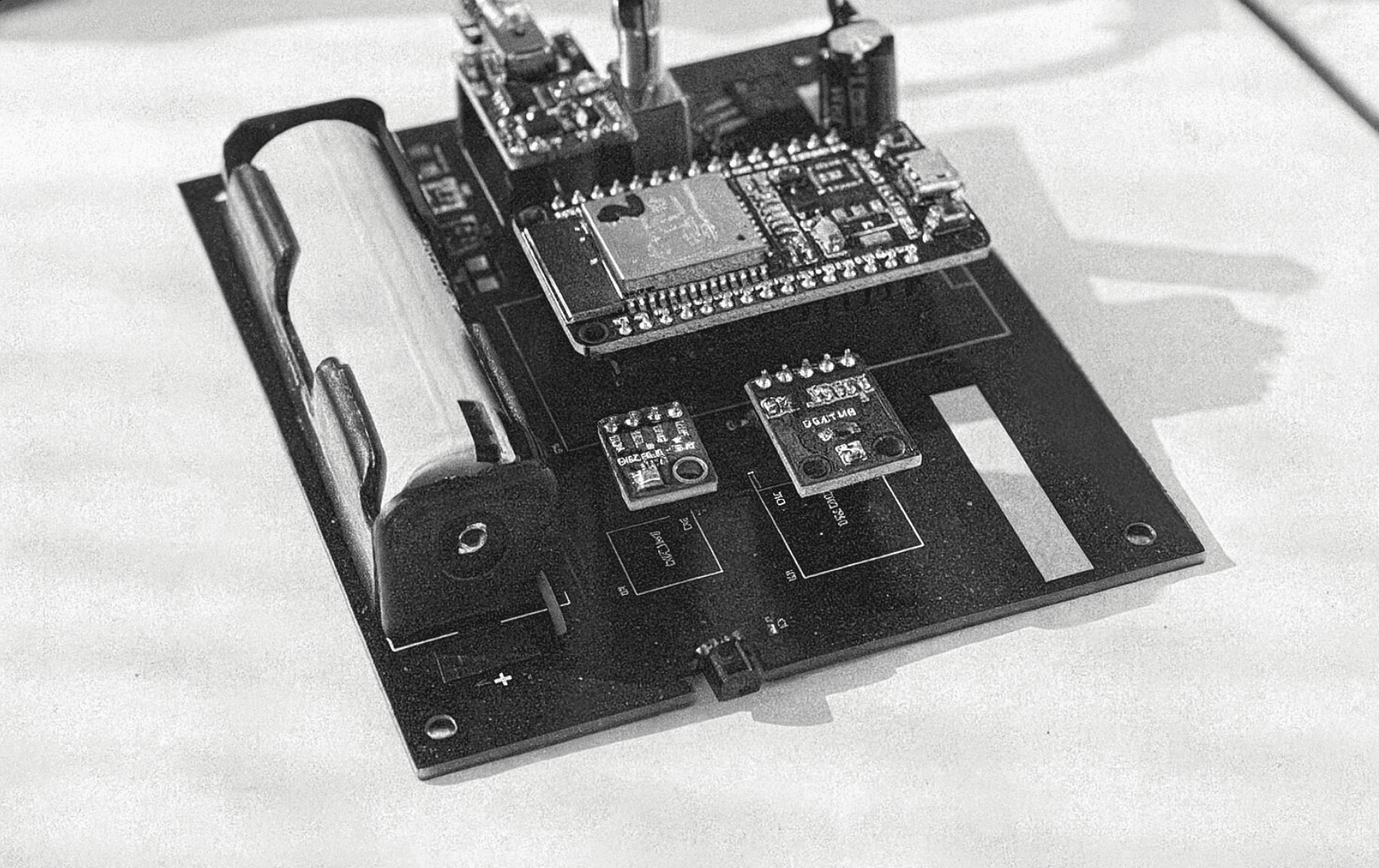

Designed a custom PCB that consolidates the ESP32, sensors, connectors, and power circuitry into a single compact board

Used strategically placed pin headers for modular sensor replacement and upgrades

Routed analog and digital lines with separation to reduce interference from the PM sensor fan motor

Implemented ground planes and decoupling capacitors for stable sensor operation

Followed outdoor-station best practices such as conformal coating options and corrosion-resistant connectors

Sensors & Sensing:

Integrated a BME280 environmental sensor to measure temperature, humidity, and atmospheric pressure with high accuracy

Added a laser-based particulate matter sensor (e.g., PMS7003 / SPS30) to capture PM1.0, PM2.5, and PM10 concentrations

Used a dedicated NDIR CO₂ sensor (e.g., SCD30 or MH-Z19B) for stable and calibrated indoor air-quality measurements

Designed proper sensor placement inside a Stevenson-style ventilated enclosure to ensure accurate airflow and protect components from direct sunlight and precipitation

Implemented sensor smoothing filters (moving average / exponential smoothing) to reduce noise from airflow turbulence and particulate fluctuations

Control & Data Processing System:

Powered by an ESP32 microcontroller, selected for its integrated Wi-Fi, low-power modes, and high-speed ADC/I²C/SPI interfaces

Developed firmware to poll sensors at fixed intervals, perform calibration routines, and compute derived metrics such as:

Absolute humidity

Air Quality Index (AQI)

Dew point

Pressure-based altitude estimation

Integrated a local display (OLED/TFT) showing key readings such as temperature, humidity, pressure, PM2.5 levels, and CO₂ concentration in real time

Implemented optional data logging and wireless telemetry via Wi-Fi to cloud dashboards (MQTT, Thingspeak, or custom API)

see also